Injection molding

The products are made by melting the thermoplastic resin with high heat and then pouring it into the mold.

The PFA has its melting point around 280 - 320 ℃ and when the its temperature surpasses this point, it liquidizes making it possible to use melting mold methods.

However, this material is very difficult to handle as when melted, is viscosity is very high and it generates some decomposition that causes corrosion of metals.

This is why when the molds are being designed, the shape, the material, etc. should be chosen very carefully.

For processing Fluorocarbon resin, we usually use screw injection molding.

Features of Injection molding

Compared to machining:

Compared to machining:

・As a surface coating is created, the product strength is higher.

・It is suitable for mass production.

・It can manufacture products with stable uniformity and quality.

Property data of Fluorocarbon resin and engineering plastics

Examples of usage and application

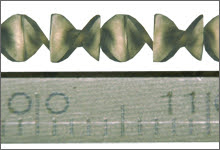

This is an example of high precision processing with injection molding.

This is an example of high precision processing with injection molding.

This picture shows a product with a screw shape made of PFA and was manufactured using mold.