Isostatic pressing

This is a wet compression molding technique.

This is a wet compression molding technique.

It uses water pressure to perform the molding making it possible to have an isostatic process.

As rubber is used mold, it is also called rubber molding.

This technique is usually used for molding metals and ceramics but it became available for molding Fluorocarbon materials.

The isostatic molding can create products with really low distortion making it suitable for thin wall products. Also, as it process the material with uniform pressure, it can create products with high strength.

By shaping the rubber mold, it is possible to mold the material making it really close to the final product.

The isostatic molding process is as shown at the picture above.

Features of Isostatic molding

・As it uses uniform pressure, it can create product with low distortion making it suitable for high-functional products.

・As it uses uniform pressure, it can create product with low distortion making it suitable for high-functional products.

・It has high flexibility with shaping making it possible to mold the material into a shape extremely close to the final product.

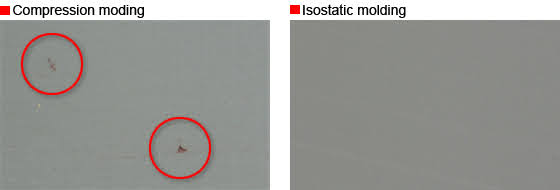

・As this technique pressures the material from all directions, it makes it possible to mold void-free materials.

|

|

| Existence of void | Void-free |

| ※写真は赤の浸透液に長時間漬けこんだ素材の断面写真です。(200倍写真) ↑翻訳テキスト無 |

|

| Void-free achieved by isostatic molding! | |